About us

Shree Nath Gravures is a trusted manufacturer of gravure printing cylinders operating since December 2021. We specialise in supplying cylinders to industries such as flexible packaging, printing, security labels, printing of tobacco products, and FMCG.

Our core business philosophy revolves around quality over quantity.

- Initially starting with a capacity of 1200 cylinders per month, we have currently increased our production to 1800 cylinders per month. Our capacity will be increased to 2500 cylinders per month by August 2024. Our primary focus remains on customer satisfaction, ensuring top-notch quality, and timely delivery of our products. We are using standard raw materials, tools, and chemicals to achieve the best results and outputs.

- Our team comprises skilled and experienced professionals who are adept at handling challenges.

- We are proud to have successfully manufactured water-based ink cylinders and delivered them to many satisfied customers.

- Operating as a system-oriented company, we ensure smooth operations that are hassle-free and efficient.

MISSION & VISION

Mission

Our commitment is to become a global leader in manufacturingprinting cylinders, offering top-quality products and services that facilitate seamless business operations worldwide.We are dedicated to surpassing our customers’ expectations in terms of quality, delivery, and cost through continuousimprovement and proactive customer interactions. Furthermore, we are committed to providing a pleasant,nurturing, and growth-oriented environment that encourages our employees to achieve high productivity and personal andprofessional growth.

Vision

Our vision is to uphold the highest standards of business ethics and organisational values. We strive to lead the printing cylinder industry by expanding into new markets, diversifying our business base, and increasing our presence in rapidly growing markets and segments. We aim to create a better society by offering products, systems, and services of superior value and quality, leveraging the latest technological advancements. Our commitment includes pursuing meaningful technological innovations, ensuring that their design and implementation reflect the skills of our workforce. We aim to meet all economic, social, and environmental responsibilities while maintaining ethical values and fostering trust-based dialogues with all our partners

OUR CLIENTS

Check our top

clients & partners

We appreciate your trust greatly! Our clients choose us and our products

because they know we’re the best. We serve 100+ Clients across Pan India

why us

At Shree Nath Gravures, we place an unwavering focus on surpassing our clients’ expectations, a testament to our profound commitment to customer satisfaction. Our operations harness the power of the industry’s leading-edge machinery, constantly upgraded with the latest software technologies, and manned by a cadre of experienced professionals. This strategic amalgamation ensures we remain at the forefront of production quality and efficiency. Complementing our technological prowess is our dedication to fostering a healthy and

positive working environment, recognizing the intrinsic link between employee well-being, productivity, and the overarching quality of our products and services.

Our approach to client interaction is characterized by promptness

and meticulous attention to detail, ensuring swift responses to

inquiries and concerns. Our follow-up communications are marked

by their gentleness and clarity, emblematic of our commitment to

maintaining transparent and respectful client relationships. By

integrating advanced technology, prioritizing a supportive work

culture, and adhering to exceptional customer service standards,

Shree Nath Gravures not only aims to meet but exceed the

expectations of our clients, thereby cementing our reputation as a

leader in the gravure printing industry.

Quality Control

Quality control is one of the essential departments of Shreenath Gravures, which is focused on a customer satisfaction-oriented quality system.

Quality Management System

Shree Nath Gravure obtained ISO 9001:2015 certificate and ISO 14001 Environment Management system certificate In 2022 and then OHSAS 18001 occupational Health and safety management system certificate in 2023

CRM- "After Sales Services"

Creative solutions and technical assistance at each and every stage.

Regular feedback from our customer is our sales mechanism

Capacity

Having an annual cylinder coating and engraving capacity of 30000 per year.

products

Printing Cylinders For Cigarette Filters

Premium gravure printing cylinders designed for cigarette filters, delivering exceptional print quality and consistency, tailored to meet the tobacco industrys demands.

Security Labels

High-precision gravure printing cylinders for security labels, ensuring intricate detail and tamper-evident features to meet stringent industry standards.

Water Base Ink Cylinders

Specialized gravure printing cylinders optimized for water-based inks, providing eco-friendly solutions without compromising on print quality and durability.

Flexible Packaging Cylinders

Advanced gravure printing cylinders engineered for flexible packaging, offering superior print clarity and consistency across a wide range of materials.

Wooden Design Cylinders

Specialty gravure printing cylinders for creating realistic wooden designs, offering exceptional detail and texture replication for various applications.

Décor Cylinders

Decor cylinders crafted for high-quality printing on home decor and furnishings, ensuring vibrant, detailed designs that elevate interior spaces.

Gift Wrap Design Cylinders

Innovative gravure printing cylinders tailored for gift wrap designs, enabling vivid, high-resolution prints that enhance the appeal of gift packaging.

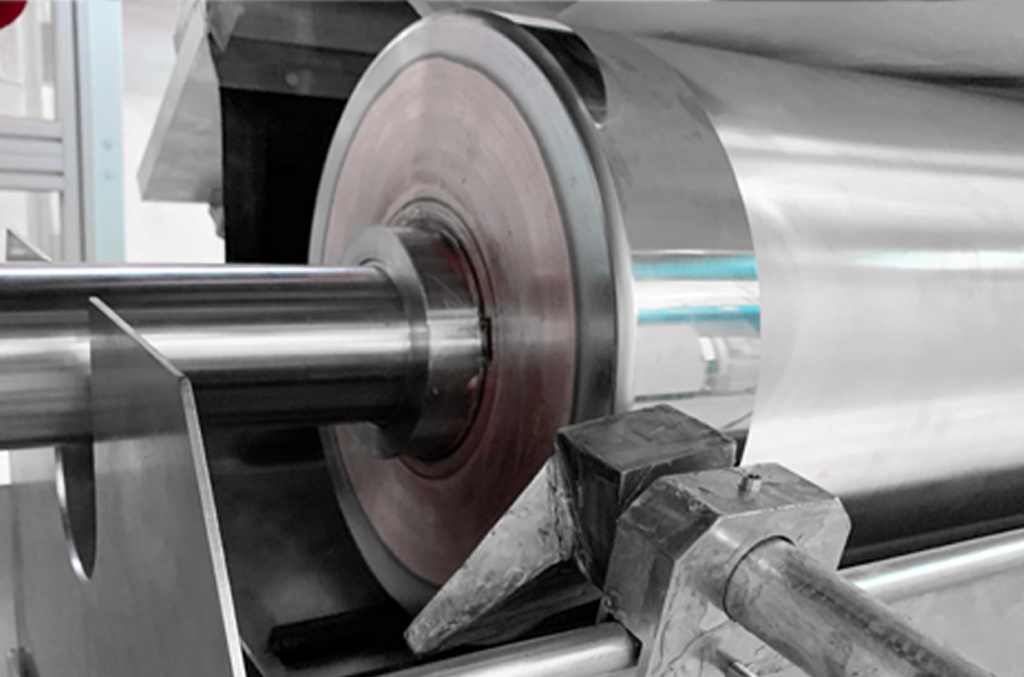

Lamination Coating C linders

Precision-engineered lamination coating cylinders designed to apply uniform coatings, optimizing adhesion and finish quality in laminating processes.

SERVICES

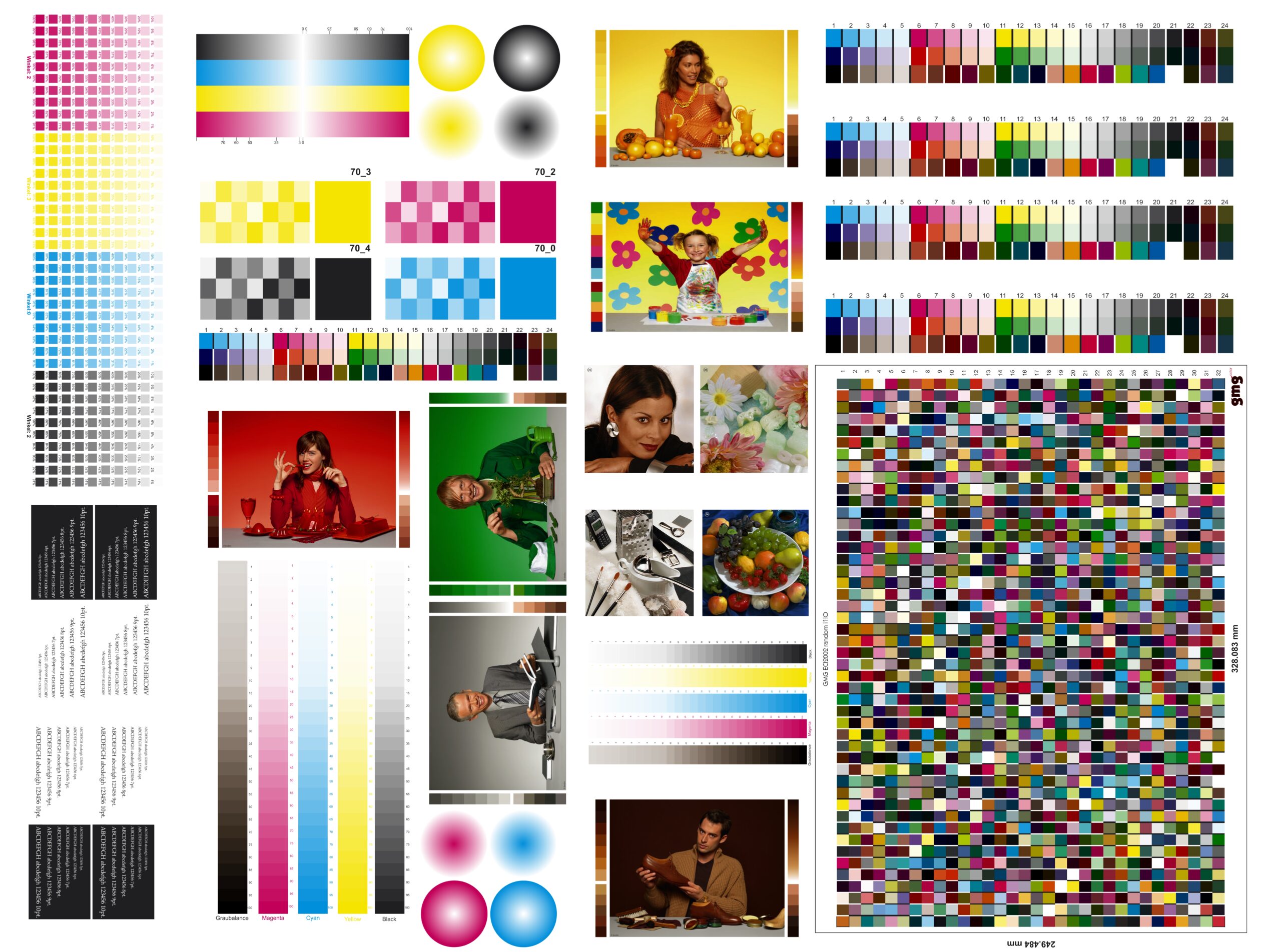

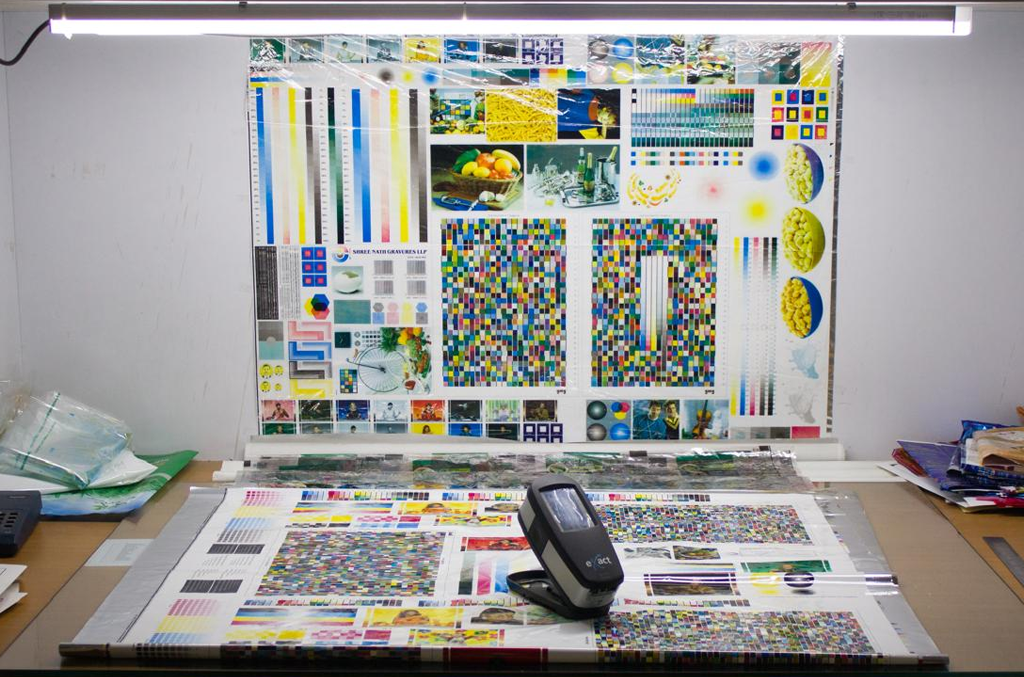

GMG / Digital Print

At Shree Nath Gravures, our standard practice is to obtain approval on GMG software-controlled Epson prints before final engraving. We strive to match more than 90% of the GMG print to ensure the final substrate proof meets our customers' expectations.

Plotter Print Out

Before engraving the cylinders, we meticulously check plotter printouts for layouts, press marks, and control color signs.

Printing Consultancy

Our experienced team handles each stage of the process, starting from the technical feasibility of the product to preprint. They also provide support to customers during the printing process.

Chrome/Dechrome & Repair Services

We offer printing companies easy and quick solutions through our cylinder filling, repair, and chromium/dechrome services. These services ensure the reusability of cylinders instead of requiring replacements, ultimately reducing costs for our clients.

Fingerprint

Fingerprint is indispensable in being capable of achieving a consistent result in different printing processes and printed designs. By measuring the printing characteristics, a profile is created by the colour management system software, and such characteristics are reflected on the actuals printing at the same proportion.

COLOR MANAGEMENT

Colour Management Applications:

Standardisation of the printing house in accordance with ISO Fogra

and Standards thereof,

- Creation of new gradation curves for colour management with different substrates

- Preparation of In-House profiles and provision of integration

with customers - Increasing the printing quality

- Elimination Of colour Inconsistencies and achievement of

printing with consistent colours. - We provide our customers with technical assistance by our

experts and upgraded