GMG / Digital Print

At Shree Nath Gravures, our standard practice is to obtain approval on GMG software-controlled Epson prints before final engraving. We strive to match more than 90% of the GMG print to ensure the final substrate proof meets our customers’ expectations.

Plotter Print Out

Before engraving the cylinders, we meticulously check plotter printouts for layouts, press marks, and control color signs.

Printing Consultancy

Our experienced team handles each stage of the process, starting from the technical feasibility of the product to preprint. They also provide support to customers during the printing process.

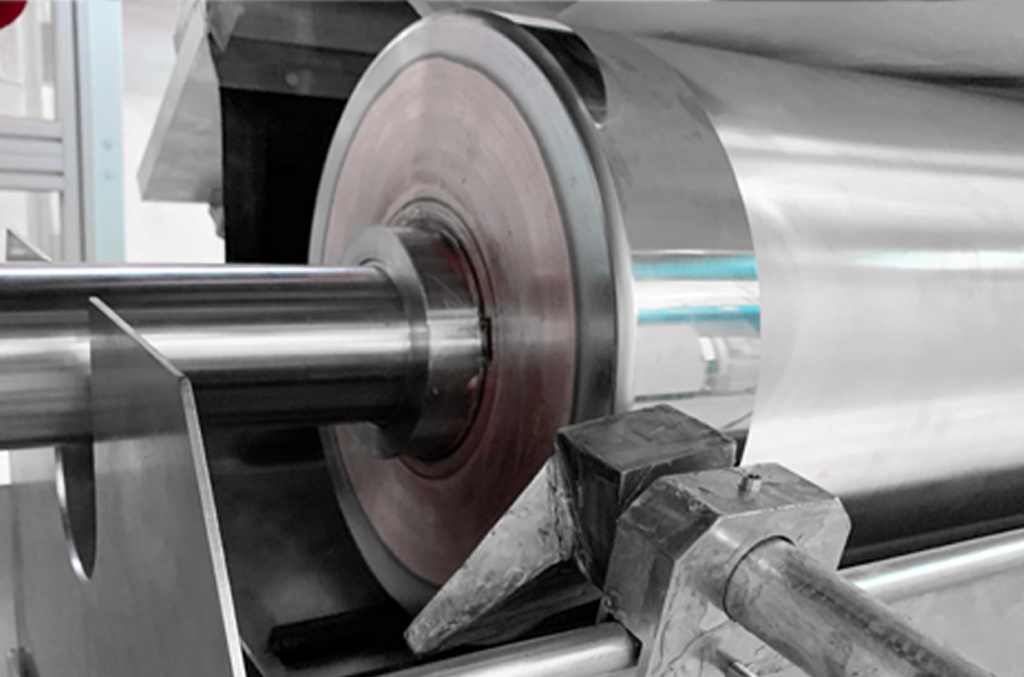

Chrome/Dechrome & Repair Services

We offer printing companies easy and quick solutions through our cylinder filling, repair, and chromium/dechrome services. These services ensure the reusability of cylinders instead of requiring replacements, ultimately reducing costs for our clients.

Fingerprint

Fingerprint is indispensable in being capable of achieving a consistent result in different printing processes and printed designs. By measuring the printing characteristics, a profile is created by the colour management system software, and such characteristics are reflected on the actuals printing at the same proportion.